Affordable Cold Room Insulation Solutions for Small Meat Lockers

- 2025-06-18

- View 4

Affordable Insulation Solutions for Small Meat Locker Cold Rooms

Getting reliable cold storage for your meat processing operation doesn't have to break the bank. For small-scale butchers, farmstead processors, and specialty meat shops, finding the right insulation equipment that balances cost and performance is crucial. Cold rooms that maintain consistent temperatures protect your product quality, reduce spoilage, and save energy costs.

The good news? You don't need industrial-scale solutions to get professional results. Many small meat locker setups thrive with appropriately sized and thoughtfully selected equipment that targets efficiency without oversized capacity.

Why Proper Insulation Matters for Meat Storage

Inconsistent temperatures in meat lockers lead to quality issues like freezer burn, texture changes, and bacterial growth. For small operations, even minor temperature fluctuations can have outsized impacts on product consistency and shelf life.

Proper insulation creates a thermal barrier that maintains consistent temperatures while reducing compressor runtime. This energy efficiency translates directly to lower operating costs – a critical factor for small business sustainability. Well-insulated walls also prevent condensation buildup that can lead to structural damage over time.

Affordable Insulation Options Worth Considering

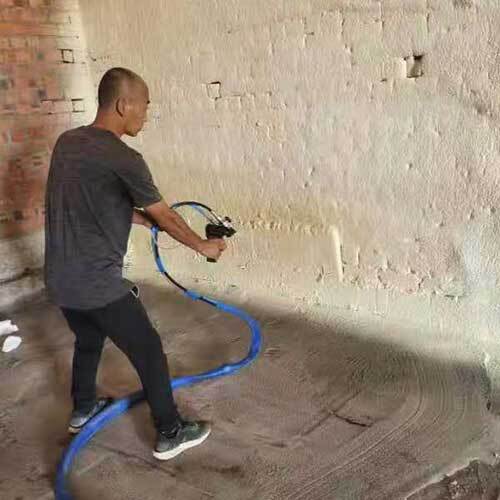

When shopping for cost-effective solutions, consider compact spray foam equipment designed for smaller projects. Unlike massive industrial systems, these compact units deliver professional results without excess capacity you won't utilize. Many butchers find that entry-level closed-cell polyurethane systems strike the right balance between performance and affordability.

For truly budget-conscious setups, modular panel systems offer surprisingly effective insulation when properly sealed. While not matching the performance of professionally sprayed foam, they provide respectable R-values at lower upfront costs.

Another often overlooked approach involves combining methods. Use spray foam at critical joints and seals while filling larger spaces with batt insulation. This hybrid approach maximizes thermal performance while optimizing equipment expenses.

Finding the Right Equipment for Small-Scale Needs

The equipment market offers several cost-effective options perfectly sized for meat locker projects:

Compact foam sprayers designed for contractors and smaller-scale operations

Portable foam kits with self-contained application systems

Refurbished or reconditioned pro-grade equipment in good condition

Package systems combining the applicator, materials, and necessary accessories

Many small operators find the How to Choose Polyurea Hydraulic Spray guide invaluable when navigating equipment options. It addresses performance requirements specific to food storage environments while considering budget realities.

Real-World Solutions That Deliver Value

Consider Terry's story – a third-generation butcher who recently expanded to a larger storefront. His budget was limited but he needed reliable cold storage for his premium cuts. By selecting compact application equipment and focusing insulation efforts strategically on critical areas, he achieved temperature stability within 0.5°C while staying 30% under budget.

Another processor found unexpected savings through a phased approach. They insulated one locker section completely before adding subsequent units over several months. This distributed the equipment investment while providing functional storage throughout the expansion.

For inspiration from similarly scaled projects, the Equipment Success Stories collection offers numerous examples of small operators achieving professional results without massive investments.

Smart Installation Tips for Better Performance

No matter which insulation solution you choose, proper installation significantly impacts performance:

Seal all joints and penetrations thoroughly – these thermal leaks compromise even the best insulation

Pay special attention to door frames and thresholds where cold air escapes

Maintain continuous vapor barriers throughout the assembly

Don't overlook floor insulation which accounts for 10-15% of heat transfer

Consider future accessibility needs during the design phase

For specialized applications, some processors explore Custom OEM Spray Solutions that adapt standard equipment to unique configurations.

Maintenance Tips to Preserve Your Investment

Protecting your insulation equipment investment extends beyond the initial installation:

Establish regular cleaning schedules for application equipment components

Inspect insulation integrity annually for signs of damage or moisture intrusion

Monitor compressor runtime patterns for early detection of insulation issues

Maintain proper air circulation to prevent moisture buildup against insulation

Document temperature logs to identify gradual performance decline

Many operations that eventually expand their capacity start with Industrial Foaming Machines Manufacturer but begin with their more compact offerings.

Making Your Equipment Investment Count

Cost-effective cold storage begins with understanding that "affordable" doesn't mean "compromised." With careful equipment selection and quality installation techniques, even modest meat locker setups achieve impressive results. When exploring options, remember that scalable solutions allow growth without complete reinvestment later.

Smart operators balance upfront costs with long-term operating expenses. Energy-efficient insulation solutions may cost slightly more initially but generate continuous savings through reduced power consumption and minimized product loss.

Your local Polyurethane Systems Manufacturer often provides valuable guidance tailored to small business needs – an underutilized resource for many butchers and processors.